solution

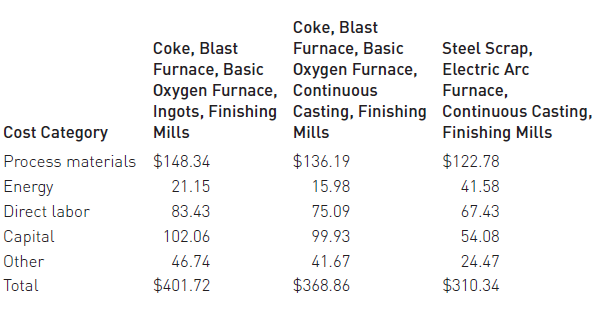

An MIT study has estimated costs for producing steel with three different technologies:

(1) coke, blast furnace, basic oxygen furnace, ingots, and finishing

mills; (2) coke, blast furnace, basic oxygen furnace, continuous casting, and

finishing mills; and (3) steel scrap, electric arc furnace, continuous casting,

and finishing mills. Under reasonable assumptions concerning input prices,

the estimated average costs per ton are as follows:

The MIT report concludes that “unless significant changes occur in other

technologies, the electric-furnace continuous-casting route will dominate

domestic production.” Why? b. At the same time, the report notes that the price of scrap (which is used in this route) “could increase as electric furnace production expands

because of the increased demand.” Why is this relevant?

c. The report also concludes that regardless of which of these technologies

is used, cost per ton is about 25 to 30% higher if wages are $26 per hour

rather than $2 per hour. What does this imply about the competitiveness

of U.S. steel producers relative to producers in other countries that pay

wages far below U.S. levels? d. If these cost figures are long-run average costs, under what circumstances would they also equal long-run marginal costs?

Ă‚Â

"Looking for a Similar Assignment? Get Expert Help at an Amazing Discount!"