solution

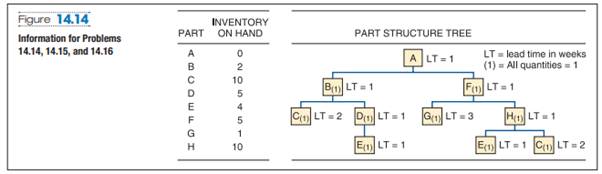

You have just been notified via fax that the lead time for component G of product A (Problem 14.15 and Figure 14.14) has been increased to 4 weeks.

a) Which items have changed, and why?

b) What are the implications for the production plan?

c) As production planner, what can you do?

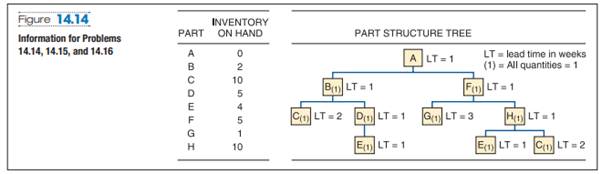

Problem 14.15 and Figure 14.14

You are product planner for product A (in Problem 14.14 and Figure 14.14). The field service manager, Al Trostel, has just called and told you that the requirements for B and F should each be increased by 10 units for his repair requirements in the field.

a) Prepare a list showing the quantity of each part required to produce the requirements for the service manager and the production request of 10 Bs and Fs.

b) Prepare a net requirement plan by date for the new requirements (for both production and field service), assuming that the field service manager wants his 10 units of B and F in week 6 and the 10 production units of A in week 8.

Problem 14.14 and Figure 14.14

A part structure, lead time (weeks), and on-hand quantities for product A are shown in Figure 14.14. From the information shown, generate:

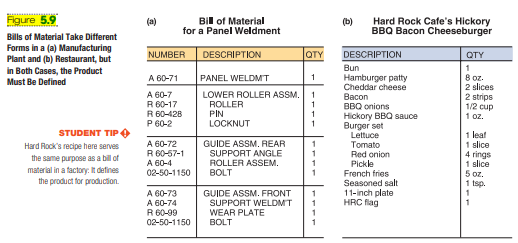

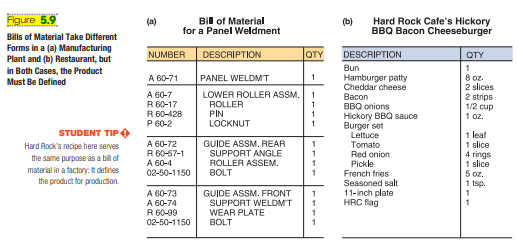

a) An indented bill of material for product A (see Figure 5.9 in Chapter 5 as an example of a BOM).

b) Net requirements for each part to produce 10 As in week 8 using lot-for-lot.

Figure 14.14

Figure 5.9

"Looking for a Similar Assignment? Get Expert Help at an Amazing Discount!"